Understanding the Key Principles of Lean Manufacturing

-

By Niharika Chaurasia

By Niharika Chaurasia

- Published on Nov 22 2023

Table of Contents

Origin of Lean Manufacturing Principles

Lean Manufacturing has its roots in the Toyota Production System (TPS), developed by Toyota in post-World War II Japan. Toyota faced significant challenges, including resource constraints and the need for efficient production. This adversity led to the innovation of Lean principles.

Key figures, such as Taiichi Ohno and Shigeo Shingo, played pivotal roles in shaping the TPS. Ohno pioneered concepts like "Just-in-Time" production, while Shingo introduced error-proofing techniques.

Lean principles have transcended the boundaries of Toyota and the manufacturing sector, finding applications in various industries globally. Today, over 70% of manufacturers worldwide consider Lean Manufacturing a strategic priority.

The influence of Lean has extended beyond manufacturing to service industries, healthcare, and software development, leading to greater efficiency and customer-centric operations.

In the upcoming sections, we'll delve into the core principles of Lean Manufacturing and explore how they drive efficiency, reduce waste, and enhance product quality.

Principles of Lean Manufacturing

In this section, we'll look at the five important ideas of Lean Manufacturing. These ideas help businesses work better and waste less. We'll show you how these ideas work in real life and share interesting facts and practical tips to use them in your work. By the end, you'll understand how these ideas can make a big difference in your business.

Customer Value

The foundation of Lean Manufacturing is rooted in delivering value to the customer. This principle requires companies to identify and understand what customers truly value and ensure that their products or services align with those needs. This customer-centric approach not only improves customer satisfaction but also eliminates waste by focusing on what matters.

Toyota started making cars when people wanted them, which helped save money on storing extra cars, made the cars better, and made customers happier.

A survey from Deloitte found that 77% of manufacturers think that focusing on what customers want is crucial for a successful business. Companies that prioritize customer value experience an average customer satisfaction increase of 12%, leading to higher retention rates.

Practical Application: Conduct market research to understand customer preferences and implement feedback loops to continuously improve products or services based on customer input.

Value Stream Mapping

Value Stream Mapping is a visual representation of the end-to-end process that delivers a product or service. It aims to identify and eliminate waste by providing a clear overview of the entire process, including the flow of materials, information, and actions. This principle allows companies to identify bottlenecks and areas for improvement.

Amazon uses value stream mapping to optimize its order fulfillment process, reducing lead times and improving inventory management.

Companies that implement value stream mapping experience a 30-60% reduction in lead times on average. A study by Aberdeen Group found that 60% of best-in-class organizations use value stream mapping to drive process improvements.

Practical Application: Create value stream maps for key processes within your organization and involve cross-functional teams to analyze and optimize the value stream.

Flow

The "Flow" principle in Lean Manufacturing stresses the importance of having work move continuously through the production process without interruptions. This means reducing delays and making sure work flows smoothly from one stage to another.

Honda adopted flow manufacturing in its assembly lines, which led to much shorter production cycles and a more efficient use of resources.

Lean organizations that implement flow principles report up to 50% reduction in lead times. Flow principles can lead to a 25-50% reduction in operational costs.

Practical Application: Design work processes to minimize handoffs and waiting times. Implement tools like Kanban to manage work in progress.

Pull System

The Pull System, as opposed to traditional push systems, produces items based on actual customer demand. It minimizes overproduction, reduces excess inventory, and ensures that resources are allocated where they are needed.

Dell's direct-to-customer model is an excellent example of a pull system. They only build computers when orders are placed, minimizing inventory costs and responding directly to customer demand.

The pull system can reduce inventory costs by 50% or more. Companies that implement pull systems report up to a 25% reduction in production cycle times.

Practical Application: Implement a Kanban system to control production based on customer demand and continuously monitor customer demand to adjust production accordingly.

Perfection

"Perfection" in Lean Manufacturing is not an unattainable goal but a commitment to continuous improvement. It involves creating a culture where all employees are engaged in identifying and addressing issues to make incremental improvements over time.

Toyota, often considered a pioneer of Lean Manufacturing, has built a culture of continuous improvement. They involve all employees in identifying and resolving problems in real-time, resulting in higher quality and efficiency.

Companies that embrace a culture of perfection report a 15-30% improvement in overall operational performance. Continuous improvement practices can lead to a 10-20% reduction in costs.

Practical Application: Encourage employees to submit improvement suggestions regularly and implement Kaizen events to focus on specific improvement projects.

These five principles form the core of Lean Manufacturing and are vital for achieving operational excellence. By understanding, applying, and continuously improving these principles, organizations can reduce waste, enhance product quality, and meet customer demands effectively.

Implementation of Lean Principles in Teams

Implementing Lean Principles in teams is a critical step in ensuring the success of Lean Manufacturing within an organization. It's not just about the principles themselves; it's about how these principles are embraced, executed, and sustained through effective teamwork.

Team Collaboration

Lean Manufacturing encourages teamwork and collaboration as a means to achieve operational excellence. Teams work together to identify and eliminate waste, streamline processes, and continuously improve. Collaboration has several key aspects:

- Cross-Functional Teams: Lean teams often consist of members from different departments, ensuring a holistic approach to problem-solving.

- Clear Roles and Responsibilities: Team members should have defined roles and responsibilities to prevent duplication of efforts and confusion.

- Effective Communication: Open and transparent communication is vital for sharing ideas and progress updates. Regular team meetings and huddles are common in Lean environments.

- Shared Goals: Teams should be aligned with the organization's objectives and the Lean principles, working towards delivering value to the customer.

Employee Training

To ensure that teams can effectively implement Lean Principles, it's crucial to provide proper training to all team members. This training should cover the following areas:

- Lean Concepts: Team members should understand the core Lean principles and methodologies, such as value stream mapping, 5S, and Kaizen.

- Problem-Solving Skills: Lean teams should be equipped with problem-solving tools like root cause analysis, fishbone diagrams, and PDCA (Plan-Do-Check-Act) cycles.

- Change Management: Lean often involves significant changes in processes and procedures. Team members should be trained in change management to ease transitions.

- Continuous Improvement Mindset: Employees should embrace the idea of continuous improvement and be encouraged to suggest and implement changes.

Continuous Improvement

One of the hallmarks of Lean Manufacturing is the culture of continuous improvement. It's not a one-time effort but an ongoing process. Here's how teams can embrace this principle:

- Regular Review: Teams should periodically review their processes and results to identify areas that need improvement.

- Kaizen Events: Implement Kaizen events, which are short, focused projects aimed at making quick improvements in specific areas.

- Feedback Loops: Establish feedback loops with team members and other departments to gather insights for improvement.

- Celebrate Success: Recognize and celebrate the successes and improvements achieved by teams, reinforcing the culture of continuous improvement.

Mastering Lean Six Sigma Principles with Sprintzeal

Lean Six Sigma is a powerful methodology for process excellence. Sprintzeal offers essential training and certification to master these principles.

Why Lean Six Sigma Training Matters

In today's competitive business world, organizations must excel in process improvement and quality management. Lean Six Sigma provides a proven framework to achieve these goals. To become proficient in Lean Six Sigma, quality training is crucial.

Why Sprintzeal?

- Comprehensive Training: Sprintzeal provides Lean Six Sigma training for all levels, from Green Belt to Black Belt.

- Certified Instructors: Learn from certified instructors with real-world experience.

- Flexible Learning: Choose from online or in-person training to suit your schedule.

- Customized Programs: Tailor training to your organization's needs for maximum impact.

- High Success Rates: Sprintzeal's training methods lead to high pass rates on certification exams.

- Post-Training Support: Get guidance on applying Lean Six Sigma knowledge in your workplace.

Sprintzeal provides a comprehensive range of Lean Six Sigma training programs, including:

Lean Six Sigma Green Belt Certification: This program is designed for professionals who want to lead process improvement projects and become experts in Lean Six Sigma methodologies.

Lean Six Sigma Black Belt Certification: For those seeking advanced expertise in Lean Six Sigma, the Black Belt program covers in-depth problem-solving techniques and project leadership skills.

Lean Six Sigma Yellow Belt Certification: Ideal for employees who participate in Lean Six Sigma projects and want a basic understanding of the methodology.

FAQ

What are Lean Production Principles?

Lean production principles aim to maximize efficiency, minimize waste, and deliver value to customers.

What are the 7 Wastes in Lean Manufacturing?

The 7 wastes in Lean Manufacturing are Transportation, Inventory, Motion, Waiting, Overproduction, Overprocessing, Defects, and Skills (TIMWOODS).

What is the 5S Model?

The 5S model is a workplace organization method involving Sort, Set in order, Shine, Standardize, and Sustain for efficiency and safety.

What is the Six Sigma Methodology?

The Six Sigma methodology uses data and statistical analysis to reduce process variation and minimize defects.

How many Lean Principles are there?

There are typically five core Lean principles, with some variations and sub-principles.

Final Thought

As we wrap up our exploration of Lean Manufacturing principles, it's evident that the road to operational excellence begins with Lean. Lean principles have reshaped industries, leading to efficiency, waste reduction, and improved customer satisfaction.

If you're ready to master Lean and Six Sigma principles, Sprintzeal offers a range of courses and certifications to equip you for success. Whether you're experienced or just starting your journey, these courses can open doors to exciting opportunities and help you drive change in your organization.

Don't hesitate; start your Lean journey with Sprintzeal today. Join the ranks of successful Lean practitioners and be the catalyst for transformation.

Popular Programs

Trending Posts

Lean Waste Management: The Ultimate Guide 2026

Last updated on Nov 28 2025

Understanding Lean Manufacturing's Pros and Cons

Last updated on Dec 30 2024

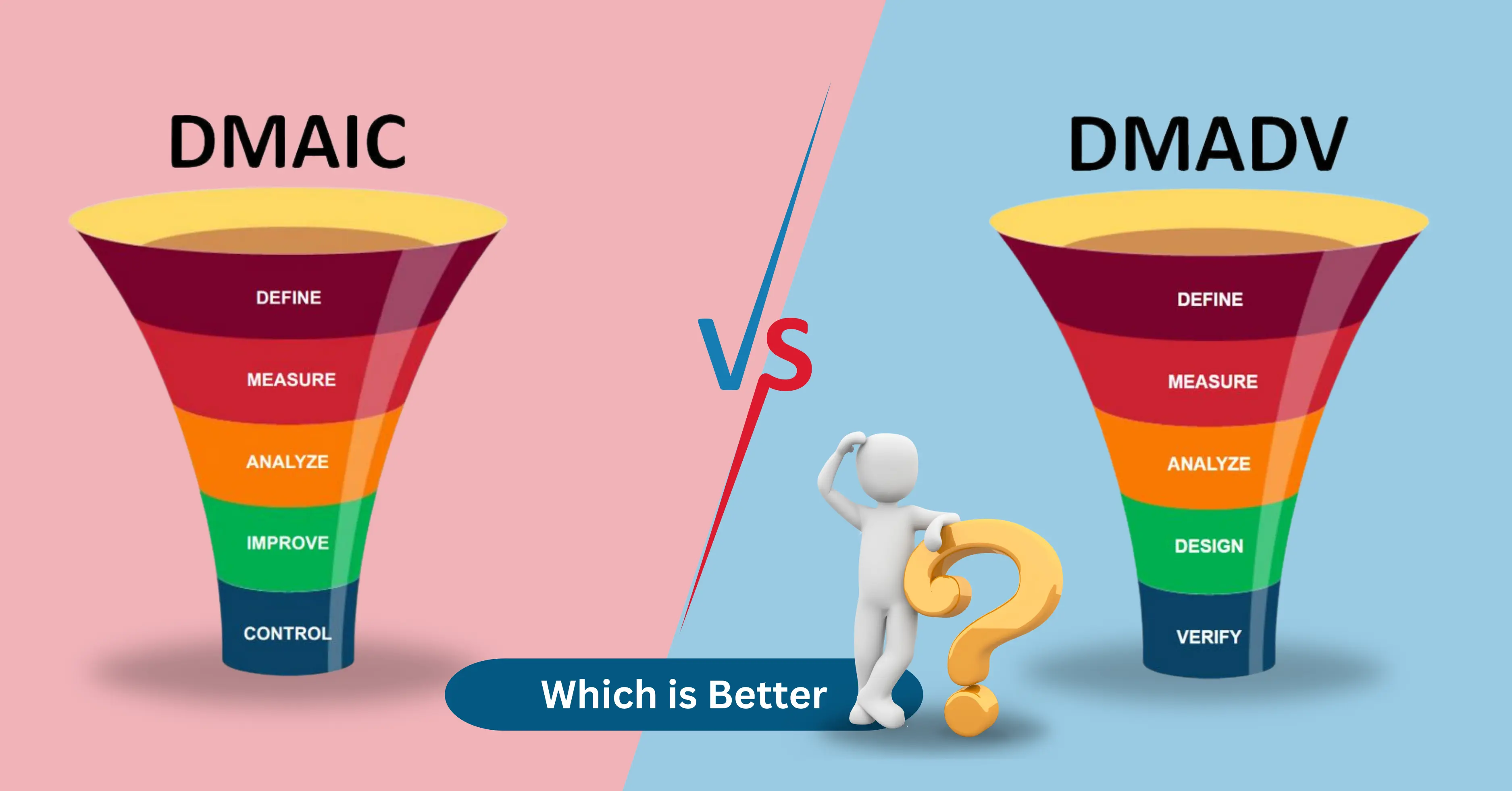

DMAIC vs. DMADV: Key Differences and Choosing the Right Six Sigma Methodology

Last updated on Nov 10 2023

Top 10 Lean Manufacturing Tools for Optimal Productivity

Last updated on Jan 15 2024

Learn about Statistical Process Control (SPC) and its top applications

Last updated on Mar 21 2023

Lean Continuous Improvement Methods for Business Excellence

Last updated on Nov 21 2023

Categories

- Other 81

- Agile Management 49

- Cloud Computing 58

- Project Management 175

- Data Science 70

- Business Management 89

- Digital Marketing 88

- IT Service Management 36

- Programming Language 61

- AI and Machine Learning 94

- IT Security 113

- Quality Management 78

- IT Hardware and Networking 28

- Microsoft Program 5

- Workplace Skill Building 15

- Risk Management 10

- Information Security 8

- Leadership and Management 10

- Corporate Training and Development 1

Trending Now

Top Career benefits of Lean Six Sigma Green Belt

ArticleLean methodology, Six Sigma methodology and Lean Six Sigma Explained

ArticleSix Sigma Black Belt Certification – Value and Career Benefits in 2026

ArticlePareto Chart in Six Sigma - Explained

ArticleSix Sigma Certification Guide - A Professional's Guide

ArticleQuality Control Explained – Six Sigma

ArticleQuality Assurance in Six Sigma Explained

ArticleQuality Assurance vs Quality Control

ArticleTotal Quality Management - A Complete Guide for Beginners

ArticleSix Sigma Certification – Everything you Need to Know About Getting Certified

ArticleLean Six Sigma on Resume for Rewarding Career Benefits

ArticleSix Sigma Yellow Belt Certification - Six Sigma for Beginners

ArticleQuality Management Interview Questions 2026

ArticleQuality Manager Interview Questions and Answers for 2026

ebookService Delivery Manager Interview Questions and Answers (With Examples)

ArticleSix Sigma Interview Questions and Answers 2026

ArticleA Supply Chain Management Guide to Mastering Logistics End to End

ArticleSenior Quality Manager Interview Questions and Answers 2026

ArticleTop Quality Analyst Interview Questions and Answers 2026

ArticleFinancial Analyst Interview Questions and Answers 2026

ArticleRisk Manager Interview Questions and Answers 2026

ArticleCompliance Manager Interview Questions and Answers 2026

ArticleOperation Manager Interview Questions and Answers

ArticleHow to Become a Quality Manager - Career, Job Scope and Certifications

ArticleHow to become a Quality Analyst

ArticleSix Sigma Certifications - Reasons Why you Should Get Them

ArticleTop Qualities of a Good Manager and a Leader

ArticleLearn about Statistical Process Control (SPC) and its top applications

ArticleCost of Poor Quality - A Detailed Guide

ArticleImplementing 5S Methodology for Better Work Efficiency

ArticleWhat Is Lean Management?

ArticleBest Six Sigma Books in 2026

ArticleLeadership vs Management - The Ultimate Guide

ArticleQuality Assurance Plan - Six Steps To Quality Assurance Plan

ArticleOperational Planning Creation, Key Elements and its Benefits

ArticleA Complete Guide to Product Life Cycle Stages 2026

ArticleDMAIC Methodology - The Ultimate Guide

ArticleSix Sigma tools for DMAIC Phases

ArticleWhat Is Lean Manufacturing?- An Overview

ArticleThe Lean Continuous Improvement Model: A Comprehensive Guide

ArticleDMAIC vs. DMADV: Key Differences and Choosing the Right Six Sigma Methodology

ArticleA Deep Dive into the Power of Lean Continuous Improvement Process

ArticleIntroduction to Lean Manufacturing- Definitions, Framework, and More

ArticleLean Continuous Improvement Methods for Business Excellence

ArticleSecret to Unlock Organizational Excellence: Stages of Continuous Improvement

ArticleLean Continuous Improvement: A Detailed Guide to Mastering Organizational Quality

ArticleLean Waste Management: The Ultimate Guide 2026

ArticleA Deep Dive into Lean Continuous Improvement Tools

Article8 Wastes of Lean - Strategies for Identification and Elimination

Article5 Lean Continuous Improvement Principles to Supercharge Your Operations

ArticleThe Ultimate Guide to Lean Manufacturing

ArticleUnderstanding Lean Manufacturing's Pros and Cons

ArticleLean Waste Reduction Strategies: Boost Efficiency and Cut Costs

ArticleTop 10 Lean Manufacturing Tools for Optimal Productivity

ArticleBeyond the Basics: Benefits of Lean Continuous Improvement

ArticleWhat are Quality Standards? | A Guide to ISO Standards

Article7 Important Types of Quality Management System

ArticleISO 9001 Standard: Benefits and Certification

ArticleA Comprehensive Guide to Quality Management Systems

ArticleBenefits of QMS Certification for Your Business

ArticleStep-by-Step Implementation Guide to ISO 9001

ArticleThe Ultimate Guide to ISO 9001: Boosting Quality and Certification Success

ArticleEssential Components of a Quality Management System

ArticleQuality Management System – QSM Approaches and Methodologies

ArticleHow to Effectively Implement a Robust Quality Management System?

ArticleExplaining QMS Documentation Structure: Benefits and Best Practices

ArticleWho Needs ISO 9001 Certification and Why?

ArticleKey Elements of ISO 9001:2015 Quality Management System

ArticleOvercoming Common Challenges in ISO 9001 Certification: Tips and Best Practices

ArticleBest Quality Management Tools

ArticleTotal Quality Management (TQM) vs. Six Sigma

ArticleQuality Manager Salary: What Freshers & Experts Earn in 2026

ArticleCertified Scrum Product Owner: Job Roles And Responsibilities

ArticleTips for Continuous Integration Testing: Streamlining QA

Article10 Quality Management Strategies Adopted by Top Managers

ArticleDMAIC for Warehouse Safety: From Hazards to Control

ArticleLive Data, Faster Fixes: How Smart Monitoring Is Rewriting Quality Control

Article